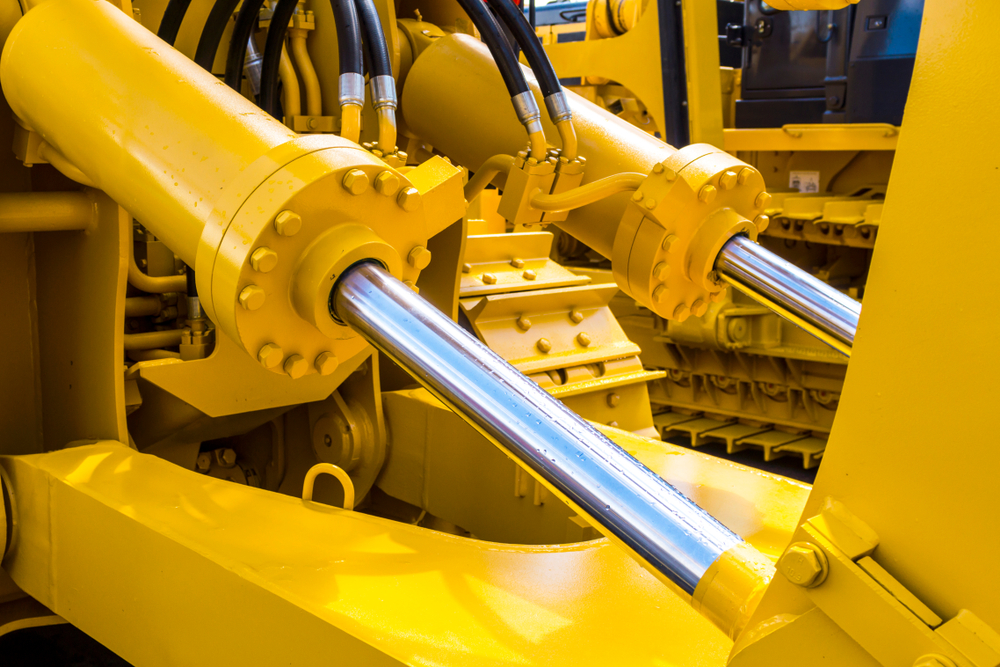

Mouldagraph is best known for the extensive repair work we do with centrifuges, the talented team and capabilities of our machining shop, and our long history with plastics. But that’s not all we do… One of the key capabilities, we wanted to showcase this month was our hydraulic repair team.

One of the core capabilities of this team is of course to provide prompt service and do good work. But what really stands out is when we hear our customers give us feedback on our engineering capabilities. They say that we are able to help them finish their hydraulic repairs because of our ability to reverse engineer the components required for repair.

The reality of the supply chain and the marketplace is that customers are often unable to obtain critical parts to repair hydraulic components. The delays to purchase a brand new component are often far too long, if the part is even available.

The superpower we offer our customers is our ability to manufacture a tailor-made repair part, so that the hydraulic repair can be completed. It allows the customer to put their equipment back into service much faster. This ‘get it fixed fast’ skill is extremely valuable to our customers in the construction, highway, paving, brick and block industries as well as many large industrial plants.